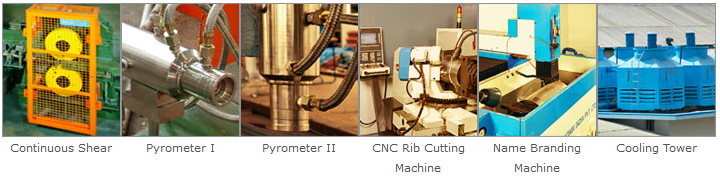

Mangala’s high quality Thermo Mechanically Treated (TMT) bars are manufactured using the most contemporary technology available worldwide and supervised by metallurgists and engineers. Through the DRI process, the basic steel is produced from virgin iron ore. The salient features of the rolling mill include an extensive billet yard for cast-wise stacking of billets, reheating furnace, pre-finishing & finishing mill, continuous shear to cut bars, roughing mill, intermediate mill, besides the most modern TMT facilities.

Our TMT steel bars are made using the ‘Quenching & Tempering’ (Q & T) technology. This technology is introduced by “SSS” Technologies. A contemporary technology, it allows the production of bars to be at par with international standards. Hot rolled from steel billets and subjected to PLC-controlled online thermo-mechanical treatment, the bars are made to pass through heat treatment over three successive stages.

1. Quenching

In the first stage of ‘Quenching’, intense water quenching is executed on the periphery while the core stays unchanged, leading to a martensitic surface and austenitic core. The quenching is done using a special water spray system.

2. Self Tempering

Subsequently, the bar leaves the quenching box to undergo a process of ‘Self Tempering’. In this stage, heat from the austenitic core flows to the surface, causing the tempering of the outer martensitic layer into a structure referred to as ‘Tempered Martensite’. The core remains austenitic.

3. Atmospheric Cooling

In the final stage of ‘Atmospheric Cooling’ that takes place on the Cooling Bed, the austenitic core is transformed into ductile ferrite-pearlite structure. The end result is a fine combination of a strong outer rim (tempered martensite) and a ductile core (ferrite-pearlite), thereby imparting strength as well as ductility.

After the quenching process, the bars are cut to desired sizes with the Shearing machines and transferred to the Cooling Bed wherein they are cooled to get the defined structure. Unlike conventional bars that are subjected to cold twisting, TMT bars have high strength, greater yield & elongation, uniform micro structure, toughness, ductility and weldability. They also bond better with cement concrete mix. Hence they are equipped with the requisite properties to provide strength to structures for enduring natural hazards.